So, what have we been doing down the boatyard these past two years? Well, Avy-J is in the water (launched last August) and ready to sail and play with. Here’s most of what we have been doing to turn an tired old classic into a potential ocean greyhound ready for a long trip:

BOW TO STERN ON DECK

- New custom made double bow roller and chainplate – thanks to mark and Mackenzie Welding

- New anchor locker bulkhead in 18mm/36,, mariner play, fully epoxied in place – thanks to Darren, Mainsail Marine

- Anchor locker painted in Danboline, strong point for bitter end

- New anchor locker lid

- New 40m 8mm chain spliced to 40m 14mm octoplait

- New 9Kg Knox anchor

- 15Kg CQR chocked on foredeck

- New midships stanchions (inexplicably missing when we got the boat – new ones fit to toerail)

- New deck glands for mast cables, VHF deck plug renewed

- Liferaft supports treated and woodsealed

- 4-man Ocean Safety liferaft, in service date

- New 4-sheave deck organisers both sides

- Hatch garage top renewed in 12mm Robbins Elite ply

- Walk-on 50W black flat solar panel installed on hatch garage

- Morse control; tension fixed, unit painted

- Engine control panel repaired

- Tiller varnished

- Cockpit cubbyholes painted in white Danboline

- Cockpit cushions

- New steering compass on port side

- Lazarette partitioned to make it useable

- Navik wind vane rebuilt, refurbished, fitted and set up

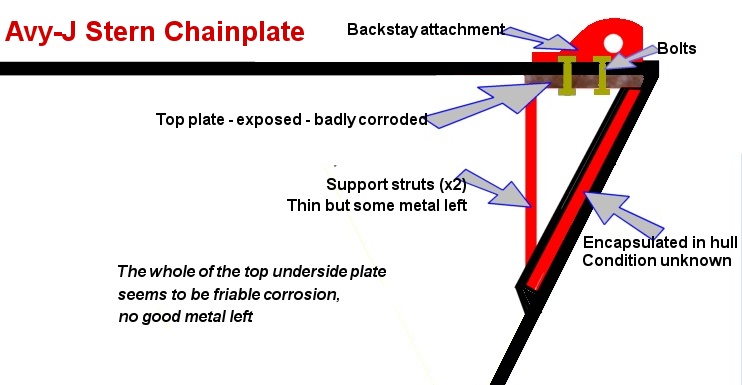

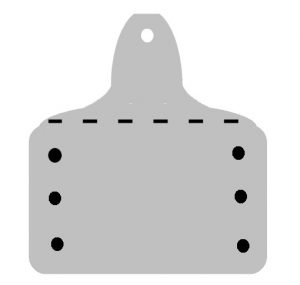

- New custom made stern chainplate – thanks to John and Norman

- New inflateable danbuoy

- ‘New’ (to us) Yamaha 2 horse 2-stroke outboard

- Emergency boarding ladder on rail

- New flagstaff

HULL

- Rudder professionally repaired – many thanks to Darren of Mainsail Marine

- 2 coats Micron 350 antifoul

- Prop antifouled with Velox

- Prop bolts tightened and locktited

- New sealant all round the underside of the toerail

ENGINE

- New raw water filter added

- New stainless exhaust elbow

- All filters replaced

- Fuel tank repaired and re-plumbed

- All fuel piping replaced – thanks to Iain

- Impellor/belts/filters/anodes all replaced

- Stern gland re-packed and greaser cleaned and refilled

- New seacock on exhaust

- Morse control serviced, new cover for morse contols in quarterberth

- New engine stop cable fitted

ELECTRICS/INSTRUMENTS

- Partial re-wire with new marine tinned cables run internally

- New VHF with built in GPS

- New NASA wind unit

- New Matsutec AIS transponder/GPS flush-mounted in cockpit

- Active aerial splitter for masthead aerial

- CTEK intelligent battery charger in re-organised battery locker

- Battery holddowns

- New engine start battery with new 1-2-both switch

- Shorepower – consumer unit + 2 double sockets

- Voltmeter

- Nav lights rewired and replaced with LED bulbs

MAST/RIGGING

- New NASA wind

- Metz manta VHF whip aerial with new RG8X cable

- New NASA LED tricolour

- New steaming light

- New wiring for lights – 3-core Oceanflex marine tinned cable

- Cable run in new external conduit

- All running rigging cleaned/serviced

- New forestay

- New reefing spectacles on mainsail

- Blocks etc for slab reefing system

GAS

- New gas locker with space for 2 Camping Gaz 907 – thanks to Adam and Darren

- New piping – thanks to John

- Bubble leak tester

- NASA gas alarm

- Neptune 2000 cooker refurbished

BILGES

- New electric bilge pump fitted with auto/manual control

- New discharge seacock for electric pump

- Whale Gusher manual pump – new diaphragm

SALOON/QUARTERBERTHS

- Quarterberths, lockers, gally area repainted in Heirloom White

- New engine cover and slides

- New steps

- Floor repainted, new carpet

- Lockers below port bunk painted in Danboline

- Hinges replaced with wood slot-ins on port side lockers

- Instrument cupboard refurbished

- New custom made curtains

- New cushions

- Headlining painted and refastened with more screws and screw covers

GALLEY

- Neptune 2000 cooker refurbished and re-mounetd more securely

- New gas pipework to cooker

- New woodwork round sink

- Whale gallery tap refurbished

- New sink seacock

HEADS AREA

- New Jabsco twist and lock heads

- New inlet and outlet seacocks

- New heads compartment floor

- Hanging Locker repaired (large section of bulkhead replaced) and relined

- Large shelved locker refurbished, wires hidden, repainted, door catch fixed

- Main door to saloon rehinged, latch to keep it open fitted

- Latch repaired on locker behind heads

- Spotlight bulb replaced with LED

FOREPEAK

- Bulkhead partially replaced on stbd side – thanks to Darren, Mainsail Marine

- Bunk head areas lined

- Bunk foot area lined

- Cove lockers refurbished/repainted

- V-berth infill repaired

- Spotlight bulbs replaced with LEDs

- Bow nav lights rewired

- Custom made bedding/cushions

OTHER EQUIPMENT

- Comprehensive toolkit and spares

- EPIRB

- Emergency VHF aerial

- Boltcroppers